11-Oct-2025

Presto Enviro

Humidity Chamber Testing is a common practice in a variety of industries such as electronics, automotive, pharmaceuticals, and material science to assess product performance in a controlled temperature and humidity environment. This method examines environmentally relevant conditions such as moisture, condensation, and extended wetness in order to determine the performance of components.

For the testing to be relevant and the results meaningful and comparable, the test procedure must follow the well-defined guidelines. This is where the standards related to national and international efforts come into play. Standards typically define the test/assessment procedure, determine environmental/temporal parameters, and define acceptance criteria so that science, safety and feasibility are consistent and a uniform baseline across differing applications.

Humidity Chamber Testing is a method of exposing products and materials to artificially controlled environmental conditions. It consists of constant temperature and varying humidity levels within a specialized chamber to test their performance, strength, and stability.

This testing determines areas of potential failure points, forecasts the lifespan of a product, complies with industry standards, and keeps products reliable and high-quality even when subjected to different levels of moisture and temperature in normal usage.

Humidity chambers are applied in industry to create conditions of high moisture, testing product longevity, determining failure points, and maintaining quality standards and regulations.

Principal Uses of Humidity Chambers

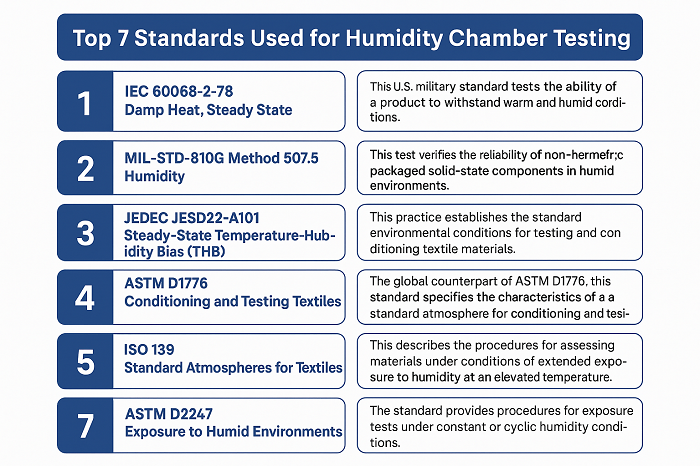

Some of the most popular standards on humidity chambers testing include IEC 60068-2-78, MIL-STD-810G Method 507.5, JEDEC JESD22-A101, ASTM D1776, ISO 139, ASTM D2247, and ISO 6270-2.

They are used in many industries, including electronics, military, textiles and construction to analyze product reliability and longevity in different conditions of moisture.

The purpose of this test is to assess the durability of electronic components and equipment by submitting them to prolonged, continuous and high humidity at a fixed temperature above the normal for a fixed period of time. It will simulate environments that are hot and humid, like in tropical or coastal areas.

This U.S. military standard tests the ability of a product to withstand warm and humid conditions, reproduced in both natural tropical conditions and forced (storage and transit) conditions.

This test verifies the reliability of non-hermetic packaged solid-state components in humid environments. It is often used under accelerated testing at high temperature and humidity to quickly reveal failures caused by moisture.

This practice establishes the standard environmental conditions for testing and conditioning textile materials. Textiles are very absorbent and their characteristics are moisture-sensitive; hence, this standardization is very important to provide reproducible test results.

The global counterpart of ASTM D1776, this standard specifies the characteristics of a standard atmosphere for conditioning and testing of textiles with a view to ascertaining their physical and mechanical properties. It supports textile test consistency worldwide.

This describes the procedures for assessing materials under conditions of extended exposure to humidity at an ultimate temperature. It is used in much of the construction and vehicle industries for corrosion resistance assessments of materials.

The standard provides procedures for exposure tests under constant or cyclic humidity conditions. It is mainly used for painted materials and coatings to assess moisture resistance.

Standards are crucial in humidity chamber testing to establish quality, reliability and safety of workmanship by providing a reproducible, solid basis for measuring performance in a variety of ambient conditions.

Main Reasons Why Standards Matter:

Organizations, including ASTM and ISO, provide standardized testing criteria to guarantee minimum quality and durability levels for a product - regardless of its manufacturer. This establishes a common ability to assess product performance.

The pharmaceutical and electronics industries are some of the industries with highly strict regulations for product performance in controlled conditions. Standards are the foundation to provide compliance with these requirements, preventing legal issues, fines, and harm to customers.

Standards allow for product performance to be tested and for the identification of potential weaknesses or failure locations with regard to humidity and temperature. This translates into stronger and more reliable products that perform in real conditions.

Identification of faults during the testing phase allows for fixes to the design before products are released to the market. This leads to avoiding material recalls, which are costly, a legal step, and reputational damage to a brand because of field loss.

Industry-tested products are likely to function as desired, leading to improved customer satisfaction, loyalty, and good vibes toward the brand.

Presto Enviro is presented as a top option for humidity chambers, due to its long-standing industry experience and a strong emphasis on quality; utilizing robust materials and the most advanced digital controls available for reliable and accurate product testing in accordance with International Standards such as ASTM and ISO. The products feature customizability, low maintenance costs, and customer service to improve product longevity in any industry.

Elevate your quality assurance process to new heights

© Copyright 2025. All Rights Reserved by Presto Stantest Pvt. Ltd.